Reading Guide

Forklift Matching Requirements

Forklift Attachment Class

Please pay attention to the flow and pressure requirements for each type of attachment. The working pressure of the attachment should not exceed its maximum value. To achieve optimal performance of the attachment, set the forklift's additional oil supply according to the recommended flow rate. If there are special performance parameter requirements, such as multiple pressure settings, additional auxiliary devices will be needed.

The attachment installation class refers to the type of mounting hooks on the back of the attachment product. Standard products come equipped with these hooks, requiring the forklift's mast to comply with international standards for proper hanging and connection.

The specifications of the hydraulic connectors at the time of product shipment.

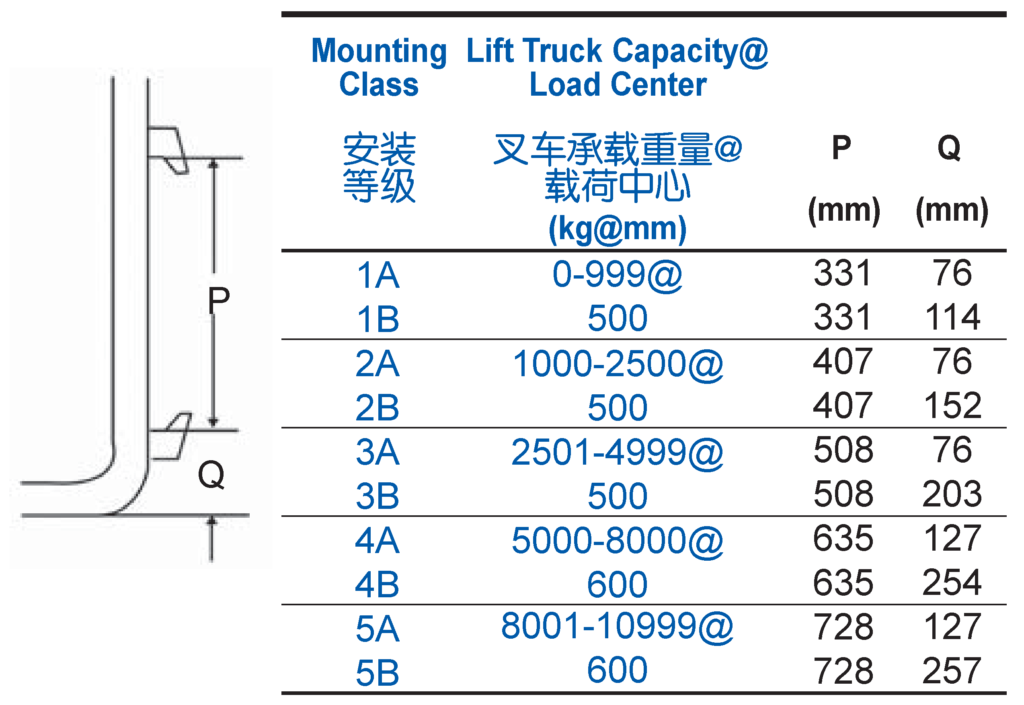

The meaning of the installation class is detailed in the following figure/table:

The standard configuration of the oil port connector is the national standard face seal type (thread specification is 9/16-18 UNF). If a special connection form is required, please contact the sales representative.